Extendable Drawbar

Fitting an extendable drawbar to your trailer can increase its versatility, particularly if you occasionally require transporting long lengths of material (building materials, pipes, joinery, etc..) or even if you want to throw a kayak onto the trailer. Extendable drawbars are great for boat trailers launching and retrieving in shallow water.

For the majority of the time an extendable drawbar would be at its normal retracted length and only extended when required. In doing so, helps keep any rear overhang within legal limits, and assists in keeping weight forward of the axle(s) to prevent trailer instability.

Rear overhang is the measurement from the axle centre (or on a tandem, the halfway point between the axles) to the end of your load. In New Zealand this is 4.0 metres and in most Australian states - 3.7 metres.

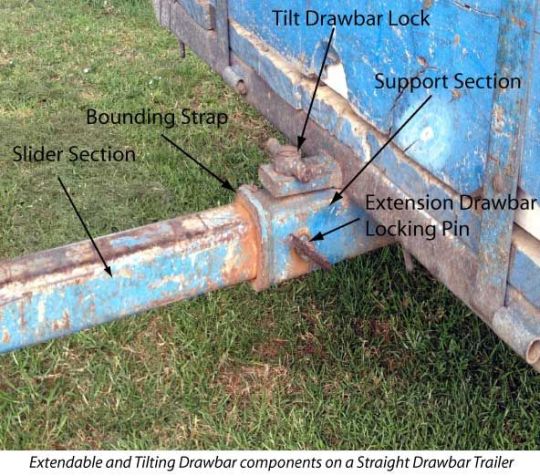

Locking pins need to be as large a diameter as possible (16mm minimum) and ideally with a high tensile strength. More than one locking pin is preferred and there should be a way of securing them to prevent them coming loose and dropping out. Locking pins should be snug within the hole in the slider and support section to prevent the holes from flogging out (stretching) and the pins from wearing or deforming.

If the extension is constantly in use, it is wise to replace the sliding section and locking pins on a regular basis as the additional stresses placed on the sliding section can have the potential to cause material fatigue and cracking and lead to early failure of the drawbar.

Electrical cable length needs to be increased to allow the trailer to be plugged into the tow vehicle when the drawbar is fully extended. Facility for this extra cable to be tidily coiled up and secured when the drawbar is retracted is needed to prevent damage to the cable and to stop it dragging on the ground. It is possible to fit the cable through the middle of the sliding section and have a spring loaded pulley arm or re-coiler (think garden hose auto re-coiler reel) under the deck to keep the cable away from potential damage. Otherwise a couple of opposing hooks on the fixed part of the drawbar for winding the cable around will do the job nicely.

Hydraulic surge brake couplings can be used on extendable drawbars, but a flexible brake hose is required between the coupling and the fixed drawbar section. The hose needs to be professionally sourced and should be made with a covering of stainless steel braiding to give additional protection to the hose. Retaining the flexible hose, when the drawbar is retracted is a bit more difficult than the cable, and care needs to be taken coiling the loose hose to prevent the hose from being kinked or damaged when securing to the trailer.

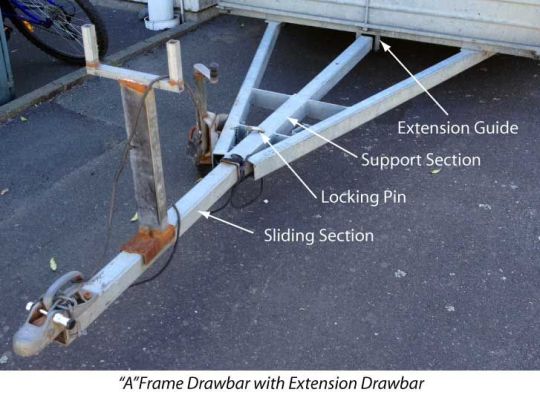

On an “A” frame drawbar of 1.2 to 1.5m long, it is not uncommon to have an extendable drawbar section that can take the overall drawbar length out to 2.4m or longer depending on the material used. Any further than 2.4m overall length and some professional engineering advice should be taken to ensure the strength of the drawbar is not compromised. And always remember to reduce the load on the trailer by at least half when using an extended drawbar.

To determine your required length for either a longer fixed length drawbar or extendable drawbar, measure the longest length material/item you need to carry and subtract your deck length from this. Divide what is left over, in half and add at least 300mm to give clearance between the load and tow vehicle, to get your extended length.

For example – if you have a kayak measuring 6 metres and a deck length of 2.4 metres (8’) – 6m minus 2.4m = 3.6m divided in half = 1.8m plus 300mm = 2.1m.

Note that the additional 300mm is only suitable if the load is relatively narrow and sits centrally in the trailer to give suitable tow vehicle/load clearance when turning. If the load is wider than 1/3 of the trailer deck width at the front end of the trailer, you will need to increase this measurement to suit.

As with all loads, the balance should be slightly forward of the axle to ensure good trailer stability and to prevent trailer sway.

See also "Tilting Drawbars" & "Drawbar Bracing/Strengthening"