Drawbar Welding

Correct welding of the drawbar to the chassis is important to prevent drawbar failure during normal use.

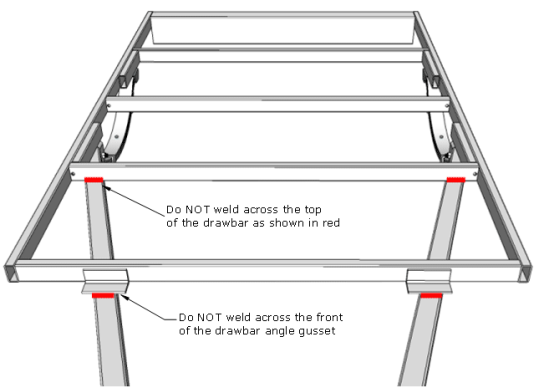

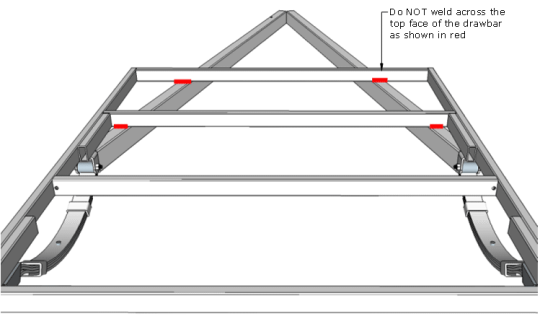

The trailer plans on this site have specific requirements for NOT welding the drawbar across the top face of the drawbar section where it intersects with the front chassis rail.

The reason for not welding the top face of the drawbar and most importantly across the front of the angle gusset is that when steel is welded, the heat from welding process alters the crystalline structure of the steel and creates a "heat affected zone" or HAZ. This HAZ is generally weaker and prone to cracking depending on the circumstances the welded section is placed under.

The drawbar does a lot of work while towing. Every little bump in the road and every turn you make transfers stress through the drawbar and compresses, twists and stretches the drawbar material constantly. The majority of this flexing occurs where the chassis and drawbar are connected and is enhanced when the trailer is constantly overloaded or unbalanced. This repeated loading and unloading (cycling) of stresses on the drawbar can create microscopic cracks within the grain structure of the tongue material especially around the HAZ.

Over time a microscopic crack can grow, and potentially reach a critical size, to a point where the drawbar may suddenly fracture and ultimately fail.

Fitting an angle gusset over the drawbar top face gives addition area for supporting the load placed on the drawbar and reduces the potential for drawbar failure.